-

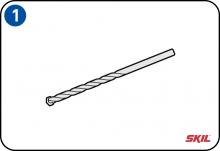

Masonry drill

You can recognize a masonry drill by the wider inset at the tip which provides the cutting edges. If you’re drilling in a hard material, you should switch the impact mechanism of your drill on. For drilling in brick and tiles you can use standard masonry drills. Or if you want to drill bigger holes it’s a good idea to first predrill the hole with a 4 mm masonry drill bit.

-

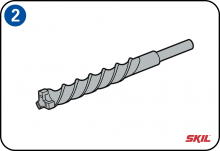

Concrete drill

The difference between a masonry drill bit and a concrete drill bit is mainly at the tip. Both those types of drill bit don’t really cut through the material, instead they chisel it away with the flat tip of the bit. The tip of a masonry drill bit is made of hard metal, while the tip of a concrete drill bit is made of diamond or Widia. This extra-hard tip makes the drill bit suitable for drilling in concrete, ceramics, granite and tiles. There are also professional concrete drill bits with 3 cutting edges, and these can even be used for drilling in reinforced concrete. Other drill bits for very hard materials are SDS+ drill bits. SDS+ drill bits can only be used in a hammer drill with a special SDS+ chuck.

-

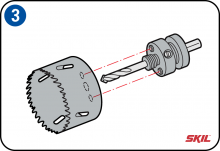

Variable-diameter holesaw

To make larger holes in stone, for example to install a mains power outlet or switch in a wall, you can use a variable-diameter holesaw. This holesaw is used with a special power drill, and has a selection of fixed diameters. The holesaw has a blade with diamond or Widia teeth.

-

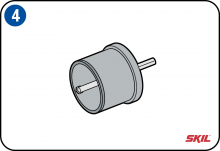

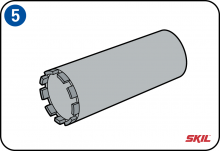

Fixed-diameter holesaw

Professionals usually prefer to use a fixed-diameter holesaw. This is much sturdier and more rigid, and is usually available in the same choice of fixed diameters as the variable diameter holesaw. The masonry drill bit at the center of the holesaw first makes a starter hole in the wall, after which the holesaw blade cuts the actual hole of the desired diameter.

-

Diamond drill

Professional diamond drills need to be cooled by water, especially when drilling larger diameter holes. They are suitable for brick, granite, sand-lime bricks, porous claystone and reinforced concrete. Diamond drills are usually mounted on a stand. A drill with a power of 1500-2500 watt is recommended.

-

Glass drills

If you want to drill in glass you need to use a special glass drill bit. Drill very carefully without using too much force. If possible, drill into the glass from both sides. It’s best to support the glass pane with a wooden plank or board.