-

Metal drill bits

A characteristic feature of metal drill bits is their sharp tip, which is necessary to ensure the drill bit cuts easily through the metal. Metal drill bits have the same diameter along their entire length, and they have a tip which is ground at an angle of 118°. These drill bits are also called High Speed Steel (HSS) drills. HSS cobalt metal drill bits are available for drilling in hard metals like stainless steel, and these have a slightly flatter tip angle of 135° for good centering when you start to drill. These drill bits are made of HSS steel with 5% cobalt, and should be cooled while drilling using special drilling oil.

-

Production of shavings when drilling

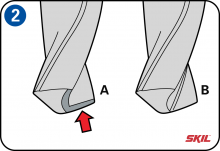

Drilling in metal causes swarf or chips (with soft metals such as brass) or shavings (with hard metals such as iron and steel). Special drill bits are available for both these types of metal. The cutting edges of drill bits for soft metals are flat (A). This ensures that these drill bits don’t ‘bite’ into the metal so easily, which means they can also be used for other soft materials such as plastic and nylon. The cutting edges of drill bits for hard metals are sharp (B).

-

Drilling big holes

If you’re going to drill large-diameter holes in metal, it’s best to first predrill using a drill bit with a smaller diameter. This will allow the larger drill to cut more efficiently, with less chance of sliding away. If necessary you can do the predrilling in a number of stages with gradually increasing diameters.

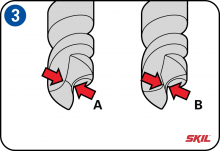

When predrilling, the diameter of the smaller drill bit (B) should be at least the same as that of the core of the larger drill bit (A). The core of the drill bit is the shortest distance between the two cutting edges. -

Drilling speed

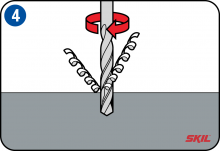

Using a drilling speed that is too high is a frequent mistake. The harder the material to be drilled, the lower the drilling speed you should use. For example, if you’re drilling an 8 mm hole in brass you should set your drill to a speed of 2500 r.p.m. Or for stainless steel, which is much harder, the right drilling speed is 800 r.p.m. A good sign that you’re using the right speed is that you’ll get nice long shavings.

-

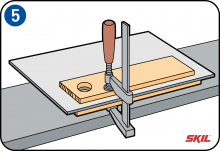

Drilling in thin metal sheets

If you want to drill in a thin metal sheet, never hold the sheet with your hands. When the drill bit cuts through the metal and comes out of the other side, there’s a danger that the metal sheet can suddenly become locked to the drill bit and shoot out of your hand. It’s better to clamp the metal sheet firmly between two pieces of wood. Then there’s less chance that it will shoot away dangerously. This also reduces the amount of burrs, which simplifies the finishing of your workpiece.

-

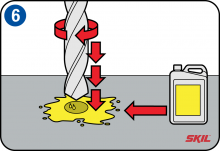

Oil the drill bit

When you’re drilling in iron or steel, it’s better to use as little force as possible. Let the drill do the work! You can use drilling oil to lubricate and cool the drill bit. When you’ve almost drilled through the metal, don’t allow the drill to penetrate the material too quickly. This will minimize burrs where the drill bit exits the metal.

-

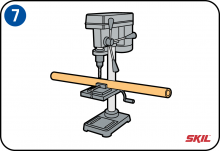

Drilling in metal pipes

If you’re drilling into a metal pipe, make sure the workpiece is firmly clamped. It’s best to use a drill stand and a vise. You can prevent the pipe from distorting – as a result of the pressure from the drill – by inserting a piece of wood of the same size and shape into the pipe. Here again: let the drill do the work, and don’t use too much force.